This pilot has been developed to address the problem of data availability on wind turbines in operation.

Windfarm owners and wind turbine OEMs have access to the data collected from the wind energy turbines in operation and they are the only players that are presently extracting value out of data at the top of the value chain. However, European components suppliers, ICT companies and ML service providers have difficulties with fully automatic access to data produced by the different systems in wind turbines in real-life operation. This fact causes certain limitations to extract full value out of data and to improve their competitiveness through digitalisation of products and services.

Enershare – Wind farm integrated predictive maintenance and supply chain optimisation

The Enershare concept articulates around the deployment of a trusted, secure, and sovereign level playing field for energy data sharing and exchange and a stack of cross-stakeholder data-driven services among energy and non-energy stakeholders. The initiative builds on 11 user scenarios that integrate intra-energy and cross-sector interactions. Furthermore, it includes validation through seven large-scale pilot projects. In this series of blog posts, we invite you to discover more about these pilot projects.

Data sharing as a key enabler for improved O&M services in the wind industry

Reduction of OPEX costs has become a key driver in the wind energy sector (particularly offshore wind) to lower the Levelized Cost of Energy (LCoE) to 7ct€/kWh by 2030, the challenging target set by the European Strategic Energy Plan (SET Plan).

Thanks to the increasing investment in digitalization technologies, a vast amount of operation data is available, and the wind industry is evolving from a reactive to predictive approach, allowing for earlier (even anticipated) failure detection and thus improving O&M tools and processes. However, much of this information remains still underexploited, avoiding their whole potential unleashed.

Although research studies show that up to 8-12% of OPEX reduction could be achieved through wind operation data sharing between data owners and users, some stakeholders are still reluctant to do it, mainly due to confidentiality, strategic positioning reasons and a certain lack of value perception from the data sharing concept.

One of the ENERSHARE pilots addresses this need through the collaborative effort between Engie, Tecnalia, Hine, Fraunhofer and the Basque Energy Cluster – representing the different segments of the wind energy value chain – in the development of advanced data sharing based services for anomaly detection in critical wind turbine components.

Advanced services for wind turbine anomaly detection

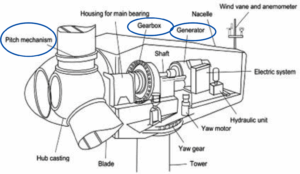

In this pilot, advanced anomaly detection services based on data sharing and machine learning (ML) techniques have been designed and developed for three wind turbine critical components:

- Gearbox: early detection of the fouling of heat exchangers using SCADA sensor data, providing real-time alerts whenever an anomalous situation arises. Based on the testing results, the underlying model (Bayesian network) exceeds 90% accuracy on detecting fouling situations.

- Electric generator: identification of short-circuit events in the stator winding of a synchronous generator with permanent magnet (PM) technology, based on a ML classifier fed with real operation or synthetic data. Testing results score >94% for anomaly detection and >92% for anomaly classification.

- Hydraulic pitch system: detection of four potential anomalies (piston cylinder seal leak, excessive friction in the cylinder, low pre-charge in the service accumulator and low pump flow) by means of a Rocket-based classifier tailored for time-series data, whose result is used to train a Ridge classifier. Based on the testing results, the underlying model exceeds 85% accuracy.

Figure 1. Critical wind turbine components addressed in the Pilot.

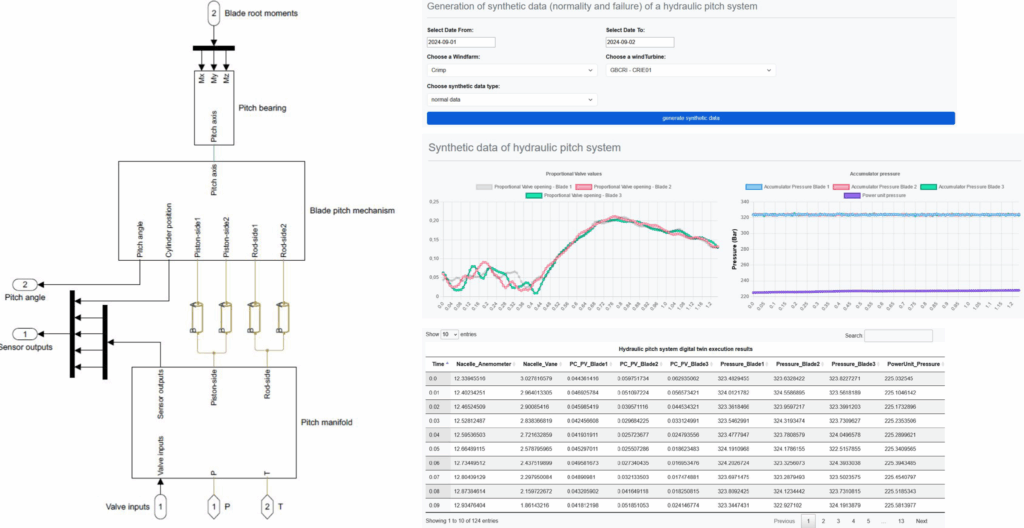

In addition, Digital Twin applications for two wind turbine critical components have been engineered as supporting tools for service development, enabling the generation of synthetic operation data which can be used to improve and fine-tune the service accuracy.

- Digital Twin of an electric generator: built on a Simulink-Matlab model representing the wind turbine drivetrain and including a PM electric generator and its power converter. It allows generating synthetic operation data of a PM electric generator, both in normality and in short-circuit conditions

- Digital Twin of a hydraulic pitch system: built on a Simscape model, featuring two cylinders, a proportional valve and an accumulator per blade. It allows generating synthetic data of a hydraulic pitch system, both in normality and in anomalous conditions

Figure 2. Digital Twin application for a hydraulic pitch system

The following link provides access to demos related to each of the services/digital twins: enershare.eu/video

Putting all the pieces together

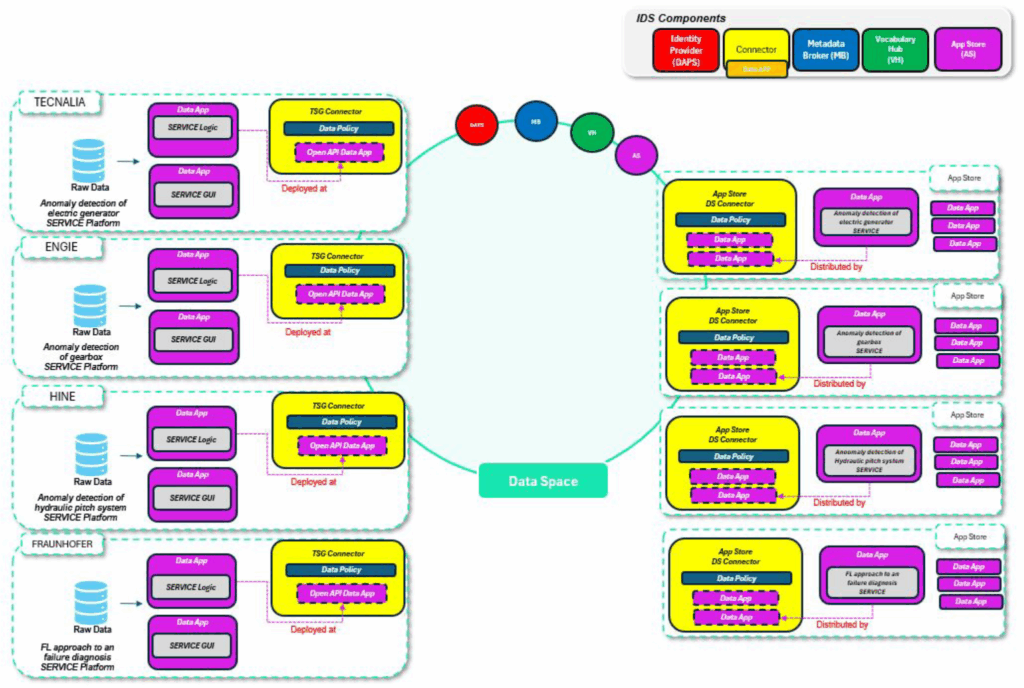

The integration of the pilot services and Digital Twin applications in the Enershare Data Space has entailed a great challenge, successfully achieved by using the TSG connector, by TNO, ensuring seamless interaction and secure data exchange between each service/application and the broader Data Space infrastructure.

Figure 3. Integration of Pilot services into the Enershare Data Space

The integration of the connector involved other key Enershare Data Space components such as the Identity Provider and the Dynamic Attribute Provisioning Service (DAPS), ensuring secure and authorized data exchanges. Additionally, the Metadata broker was also integrated, providing the metadata (aka Self Descriptions) of the linked connectors and enabling discoverability within the Data Space.

The Vocabulary Hub was used as a valuable tool to upload the ontologies required for the different pilot use cases. By leveraging the Vocabulary Hub, users can easily access and explore the detailed properties, classes, and relationships defined within the ontologies.

The Pilot services have been successfully registered in the App Store, making them accessible to other participants within the Enershare Data Space.

Impact and benefits for the wind energy sector

The pilot has delivered a digital platform design and development specifically tailored for wind farms, enabling data sharing and ML based services between data owners and data users with clear value propositions for each other and a great potential impact for the wind energy sector.

- Early anomaly detection services for critical wind turbine components (gearbox, electric generator, hydraulic pitch system)

– Minimizing downtime and increasing availability

– Reducing maintenance costs

– Extending component lifetime

– Enhancing decision-making with data analytics - Digital Twins for electric generator and hydraulic pitch system

– Better knowledge of behaviour during fault events to improve component design

– Training of failure classifiers

– Enhancing operation - Federated Learning Approach to an anomaly detection service

– Solving data sharing and confidentiality problems

Win-Win approach through collaborative effort

The Pilot is part of ENERSHARE project for an EU Energy Data Space, based on a joint effort of:

- ENGIE: data owner (own datasets and connection to Darwin Data Platform) and service provider (anomaly detection of gearbox).

- Tecnalia: data owner (synthetic data) and Digital Twin developer for PM electric generator; data consumer and service provider (anomaly detection of PM electric generator service).

- HINE: data owner (synthetic data) and Digital Twin developer for hydraulic pitch system; data consumer and service provider (anomaly detection of hydraulic pitch system).

- Fraunhofer: data owner (extensive dataset of real operational offshore wind farm) and Federated Learning-based service provider.

Basque Energy Cluster: pilot awareness and dissemination to the Wind Energy value chain, business models analysis and stakeholder engagement.

For a hands-on experience, try it on ENERSHARE App Store: